Unusual Location, Unusual Audience.

On Wednesday the 23rd of September (Australia), Tesla held their annual shareholder meeting in the car park of their Fremont, California Factory. Yes, that’s right, in their car park. The audience were each seated in their own private Tesla cars to comply with COVID-19 restrictions. This obviously created many unique challenges, but the attendees seemed to be having a great time, honking their horns with approval with everything announced.

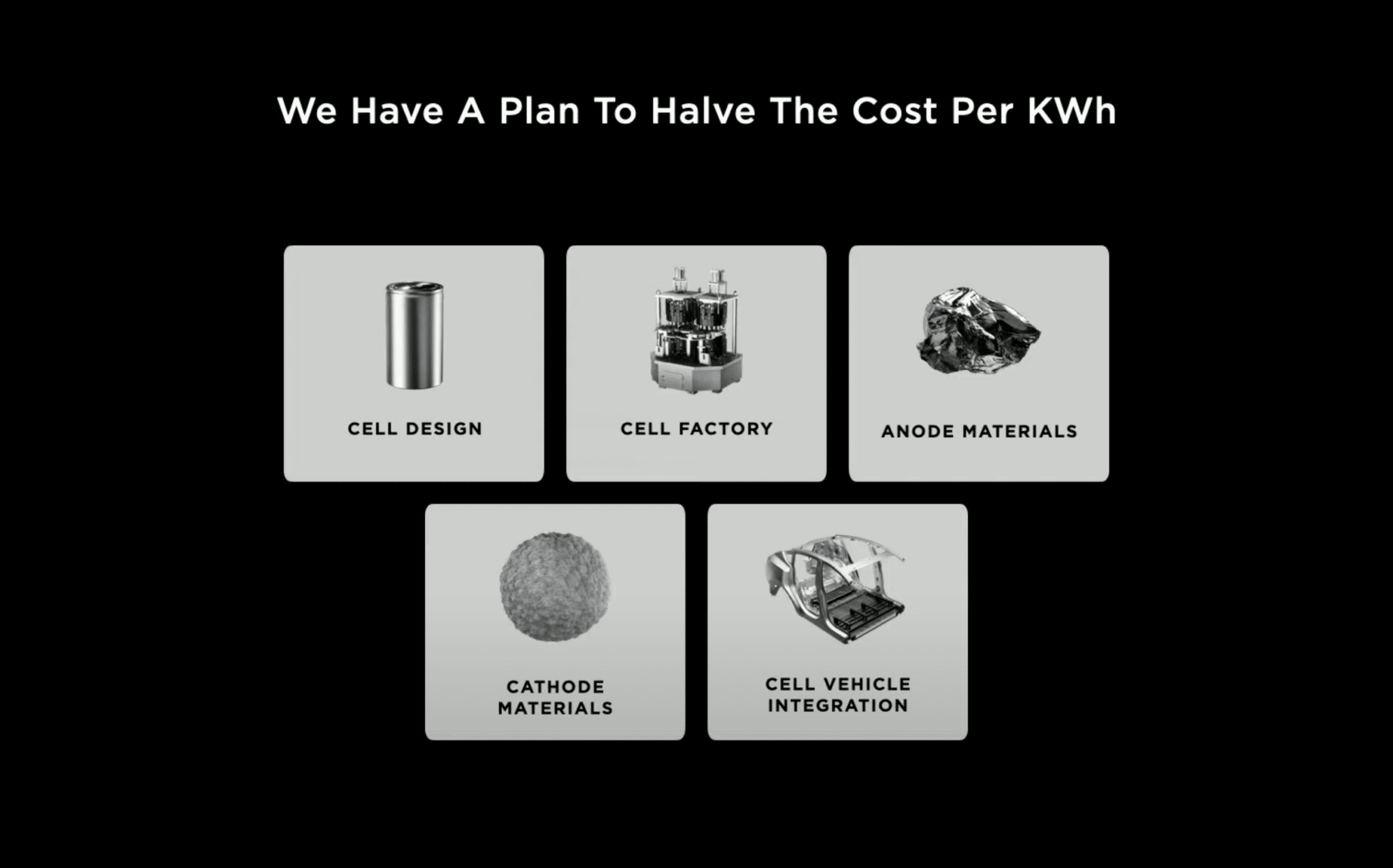

Tesla Is Doing Everything They Can To Make Batteries More Affordable.

If there’s one thing to take away from Battery Day, it’s that Tesla is doing everything they can to make their products as affordable as possible. Their goal? Halve cost per kWh costs by 2025! Their strategy to achieve this is by implementing a new battery cell design, improving efficiency of their factory production processes, integration of new materials, and significant changes to the structure of their cars.

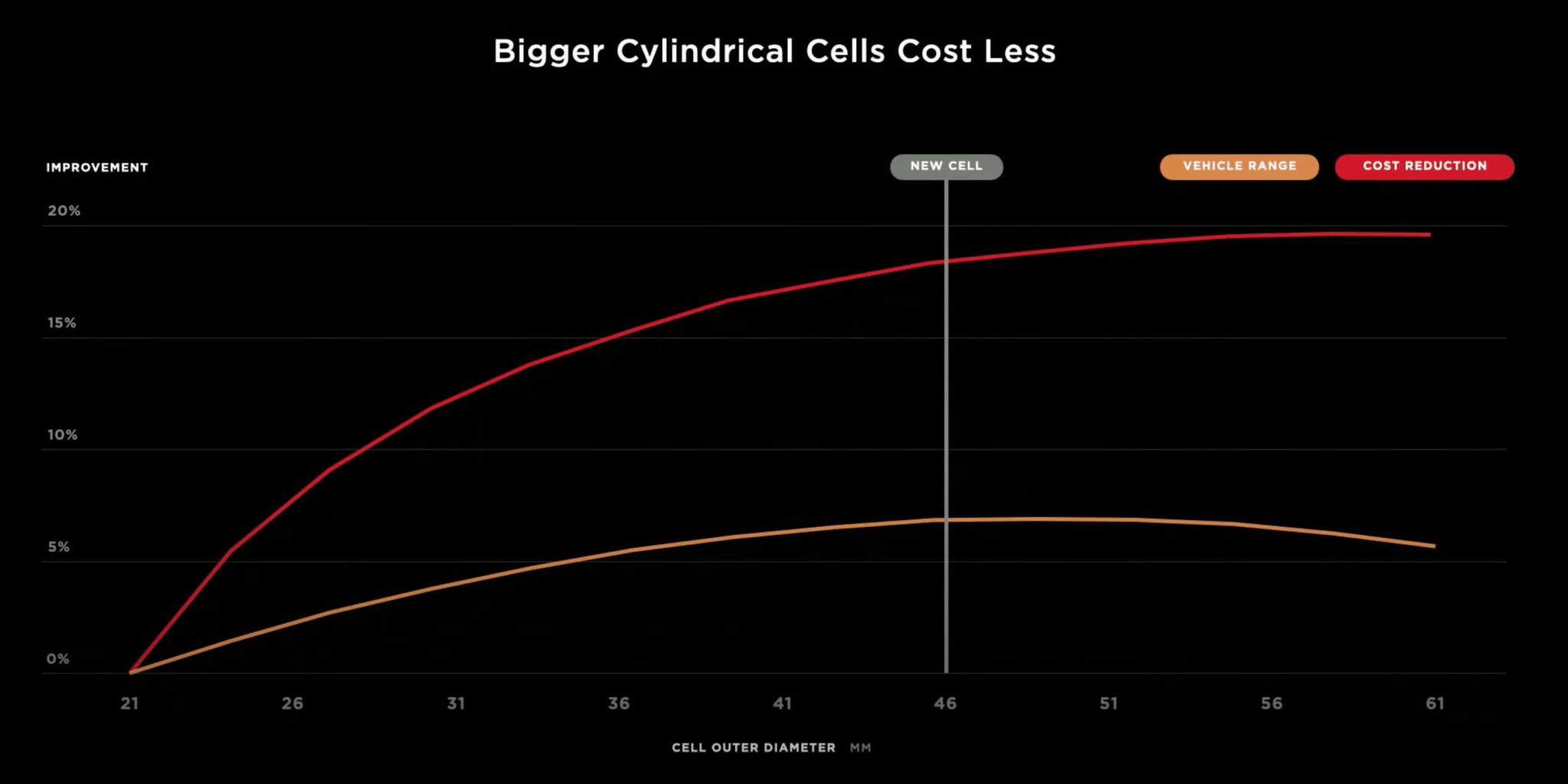

New Battery Cells, Featuring ‘Tabless’ Design.

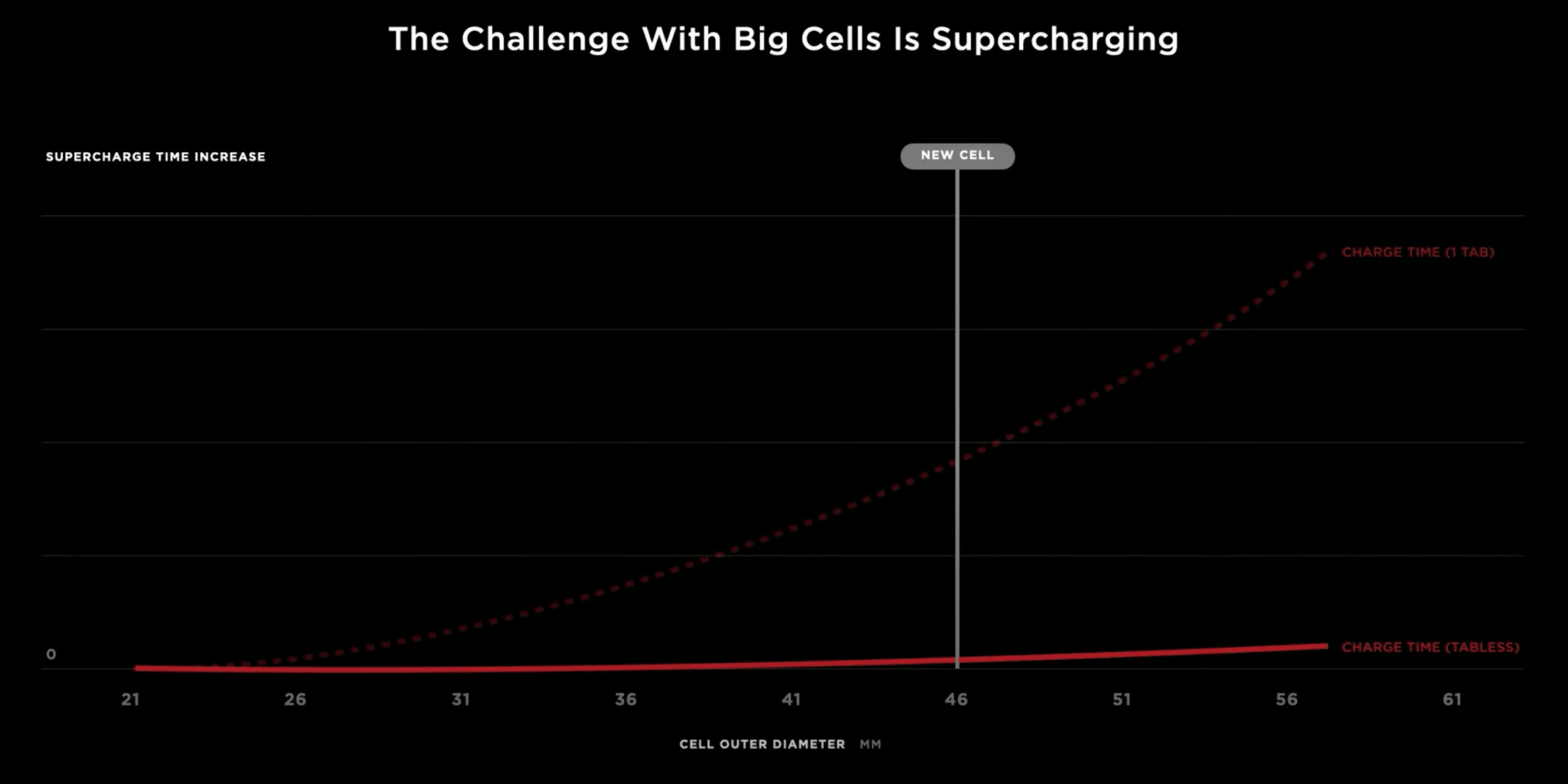

Tesla unveiled their new Cell Design called the 4680 (46mm in diameter and 80mm in height) to replace their current cell design, the 2170 (21mm in diameter and 70mm in height). They noted that increasing the cell outer diameter, you’re able to improve vehicle range and reduce costs up to a certain “sweet spot” before vehicle range starts declining. By removing the “tabs” in their cells, dozens of connection points can be added, allowing these larger form factor cells to retain supercharging capabilities, reduce cell costs, and simplify manufacturing.

Replacing And Integrating New Materials

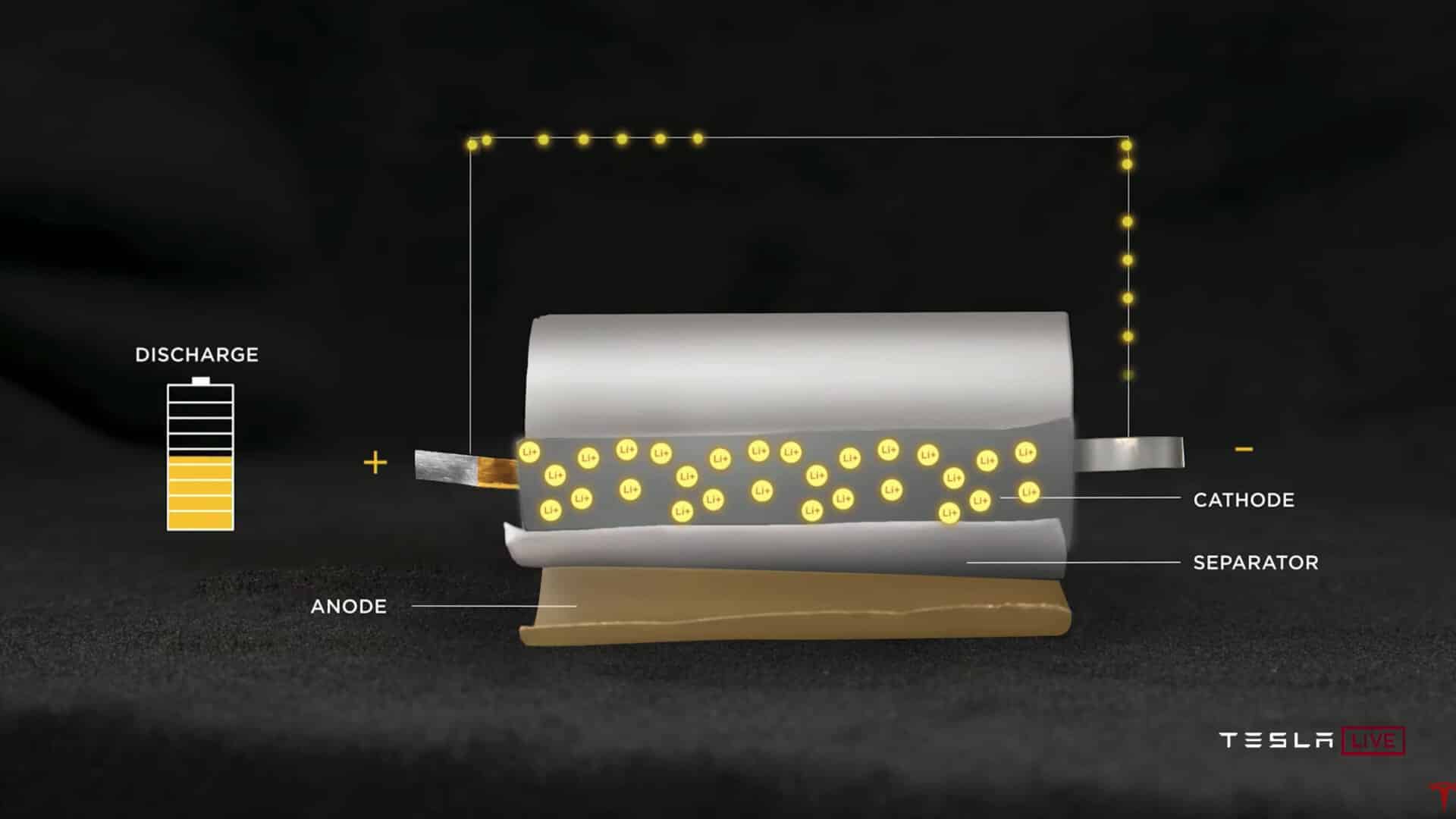

Tesla is integrating new materials to use for anodes and cathodes in their batteries. I won’t go into too much detail about the science of these new materials, but the anode is the battery electrode that electrons flow out of whilst discharging, and the cathode is the part where electrons flow into.

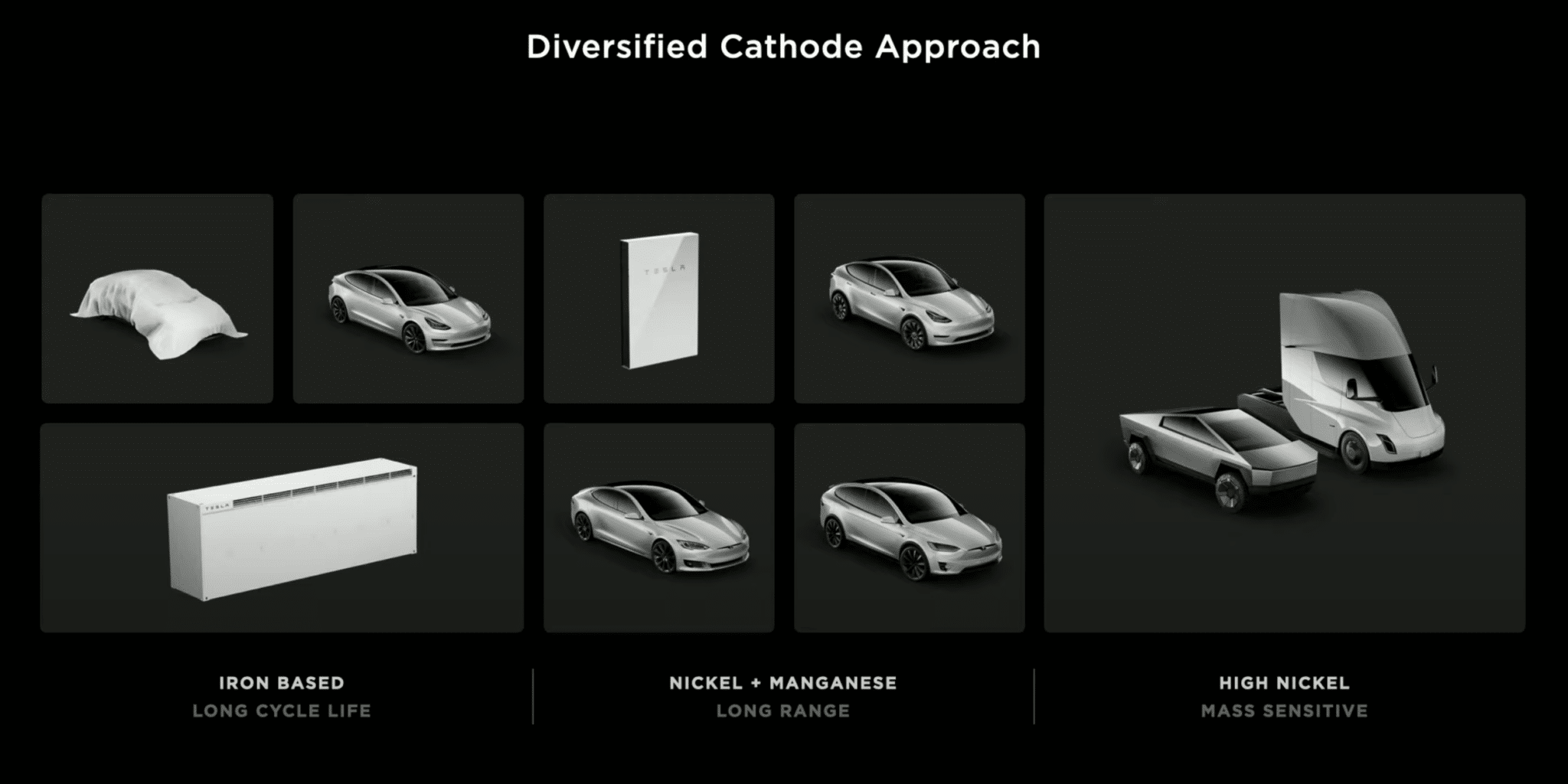

Elastic gel coated silicon will be used as the anode, reducing costs and increasing energy density. Tesla planned to replace their current cobalt cathode with Nickel for better energy density, however, Nickel isn’t as stable as Cobalt. This instability can result in faster battery degradation, which is definitely not ideal. To best utilise Nickel, Tesla will implement different cathode compositions depending on the usage, illustrated below:

To accomodate the changes in materials, Tesla announced they will be building a new cathode production factory. The location of this factory is still unknown, however, rumours indicate that it could be in Austin (Texas) or Tulsa (Oklahoma). Having their own cathode production factory reduces supply chain costs and allows a simplified production process that makes cathodes 76% cheaper and diminishes wastewater to zero.

What Does All This Mean For Solar Energy?

Tesla is working tirelessly towards lowering the cost of sustainable energy to the point where it’s affordable and accessible for everyone. Battery day was a chance for Tesla to showcase their strategies for achieving this as rapidly as they can. For the sustainable energy industry, this means a more affordable battery solution will likely be available in the near future. Currently, affordability is what’s holding back the growth of the Powerwall 2, which mightn’t be an issue for much longer.

$25,000(uSD) Tesla Car?!

We’ll cover this very soon… Be sure to subscribe to our newsletter so you don’t miss out!

Watch The Full Presentation Here.